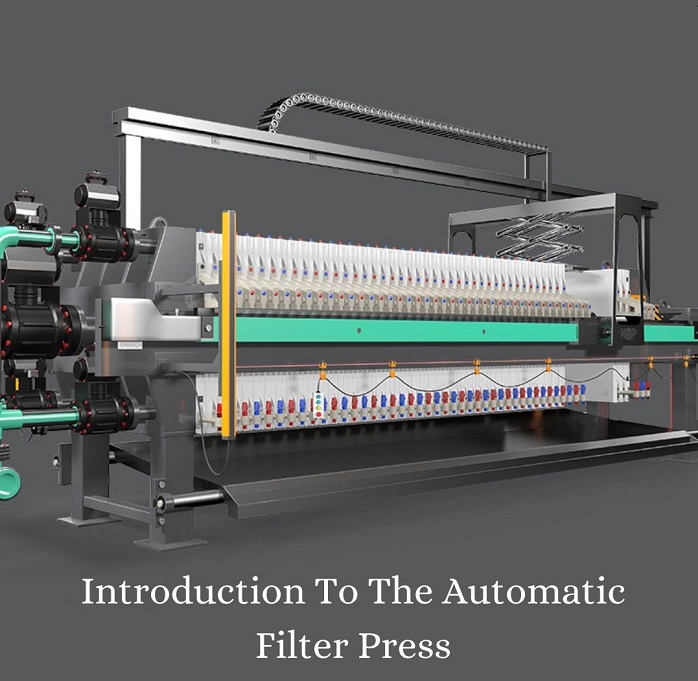

An automatic filter press (also known as a plate-and-frame filter press) can be found in just about any industry that manufactures food, beverages or pharmaceuticals — which, coincidentally, means that you probably consume products that were made using an automatic filter press on a daily basis. The design of the machine hasn’t changed much since it was invented in the late 19th century; however, what has changed is the technology behind the design. Nowadays filter press manufacturers use automated controls and high-speed pumps to make sure the system runs smoothly and efficiently at all times.

Which Type Of Filter Should I Choose?

For example, a filter that removes bacteria will not necessarily remove all harmful microorganisms. Filters also differ in terms of chemical resistance. It’s important that you choose a filter with sufficient chemical resistance for your particular situation and make sure that it’s compatible with other system components (for example, is it going to be compatible with your drainage system). Choose a product based on its total life cycle costs—there may be an initial investment when buying filters, but you should weigh that against how much you’ll save in maintenance costs over time. In general, automatic belt filters are more expensive than cartridge filters; however, their low-maintenance costs might make them worth it in some situations.

What Is An Automatic Filter Press?

A filter press is a machine that uses hydraulic pressure in order to separate particles of different sizes from each other. In particular, an automatic filter press uses a combination of levers and gears in order to automatically separate substances using vacuum and mechanical force. Although still somewhat uncommon, these machines are becoming more and more common in scientific laboratories due to their precision and convenience. However, since they are relatively new inventions, you may have never heard of them before! This guide will give you a full overview on automatic filter presses—including how they work, what kind of substances they can separate, and who might use them for.

How Does An Automated Filter System Work?

An automated filter press is a self-contained system with one large container and multiple smaller ones. As materials in your desired form come into contact with water, they automatically pass through different layers of a filtration medium. The automated filter press can process volumes of materials at high speeds while keeping out unwanted particulates and foreign matter. These systems are completely sealed and must be maintained regularly in order to ensure full quality control and productivity. A new level of efficiency is available with automatic filters that utilize only one-fifth of the electrical energy used by traditional, manual systems. Why go through all that effort when you could put your time toward other business activities? With an automatic system, your material will flow into pipes leading directly from your processing site.

How Much Time Will An Automated System Save Me?

With a traditional centrifugal filtration system, there is no such thing as a typical day. In other words, during your first two years in business, you’ll need about 50 hours per week devoted solely to cleaning and backwashing your filter, packing it with media and running batches. And that’s on top of managing all of your other tasks. With an automated system, that time can be cut down by more than half! On average, most plants save between 20-40 hours per week when they upgrade their filtration system.

Do I Need To Hire A Professional To Install My System?

Many people wonder if automatic systems are really worth it. They seem expensive, and automatic machines have a reputation for being extremely complicated. While these might be reasons why many people avoid them, they aren’t valid objections for everyone. First of all, remember that filters can save you time in both installation and maintenance; no one wants to sit around waiting for their filtering system! Membrane filter plate systems are cheaper than manual ones because they don’t require nearly as much labor: once you buy an automatic filter press, you won’t need to pay someone (or multiple someones) to help operate it every single day.

Can Anyone Use An Automatic System?

As with most new technologies, automatic systems can seem a bit complicated at first. However, there are applications that are suitable for nearly any business. They may require some tweaking and customization, but they can allow a small business owner to reduce labor costs significantly—saving both time and money. While larger businesses will probably stick with manual systems due to their high cost of entry, smaller companies could benefit greatly from an automatic system without breaking their budget. If you want peace of mind while your employees take care of other tasks around your facility, an automatic filter press is likely a good investment for your company.

What Are The Most Common Types Of Filters?

Knowing what types of filters are used in your industry is key when setting up an automatic filter press for your company. Depending on how intricate your filters are, it could take a lot of time and money to design an automatic filter press from scratch. Look into some of these common types of filter presses before making a decision on which type would be best for you. What type of filtration do you use? Do you know what each one does? Use them properly? Let’s look at three common types: depth filters, drum filters, and cartridge filters.

Do I Need New Filters For Each Cycle Or Can I Wash And Reuse Them?

Although filters can be washed and reused, you will eventually need to purchase new ones. If you are on a budget, then it may be best for you to continue washing your old filters and adding new oil each time. However, if cost is not an issue, it’s recommended that you simply replace them each time in order to avoid breaking down other parts of your equipment along with just replacing new filters. Since cleaning them will take up a good amount of time as well as put wear and tear on other equipment such as hoses or nozzles, it’s probably not a good idea unless money is tight.